Oil & Gas

Upstream to downstream turbine, compressor, and rotating equipment life-extension for offshore platforms and refineries.

The MRO that keeps your classic turbines alive.

Flysquawk Integrated Sdn Bhd is Malaysia's trusted Maintenance, Repair, and Overhaul (MRO) partner — dedicated to revitalising ageing industrial and aviation rotating equipment such as turbines, compressors, and pumps.

"Old is Gold — if cared for by the right hands."

While others rush to replace, we restore.

We bring old turbines and compressors back to life with precision, patience, and passion — preserving the machines that once powered Malaysia's growth.

Our mission is to help industries preserve their engineering legacy, protect capital, and achieve sustainable performance — without the financial burden of constant replacement.

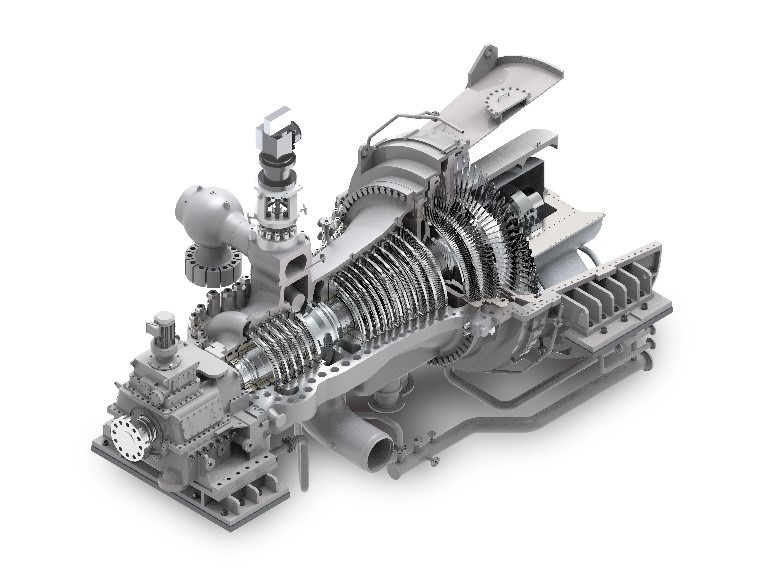

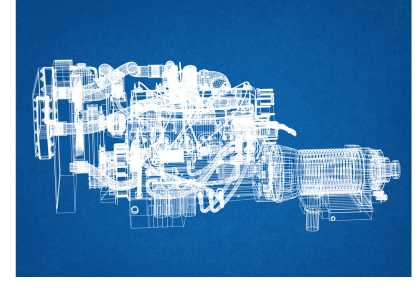

End-to-end reverse engineering and manufacturing of steam turbines up to 4 MW.

Expert maintenance and repair of high-performance compressor systems for optimal efficiency.

Specialized pump restoration services ensuring reliability and extended operational life.

Advanced replication and improvement of legacy components using modern manufacturing techniques.

On-site diagnostics, maintenance, and emergency repair services across Malaysia.

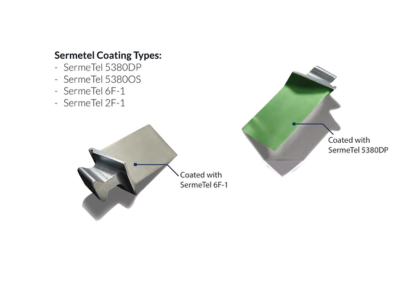

Ultra-thin, high-durability coating for corrosion resistance and precision surface finish.

Precision NDT services for early defect detection and long-term reliability of rotating equipment.

Trusted engineering stewardship across Asia’s most demanding sectors.

Upstream to downstream turbine, compressor, and rotating equipment life-extension for offshore platforms and refineries.

Steam & gas turbine rehabilitation for thermal plants, combined cycle facilities, and emerging renewable assets.

Propulsion, auxiliary turbine, and offshore platform systems maintenance for naval, shipping, and FPSO assets.

End-to-end turbine, pump, and boiler support for mills, refineries, and biomass power plants nationwide.

Aero-derivative turbine restoration, component reverse engineering, and fleet sustainment for regional operators.

Flysquawk Integrated Sdn Bhd is a Malaysian-based restoration-first Maintenance, Repair, and Overhaul (MRO) partner specialising in rotating equipment — aviation engines, industrial aero-derivative turbines, steam turbines, centrifugal compressors, centrifugal pumps, and precision reverse engineering.

Our core philosophy: restore before replace. We believe ageing industrial assets — if restored with technical precision and craftsmanship — can deliver decades more reliable service while protecting capital, reducing waste, and preserving industrial heritage.

In 2025, Flysquawk was officially recognised as the MRO Partner for PT Nusantara Turbin dan Propulsi (NTP) — Indonesia's leading turbine and propulsion specialist with 36 years of certified excellence — specifically for rotating equipment services in Malaysia's palm oil industry.

This partnership brings together NTP's world-class technical capabilities (FAA, DGCA, ISO certifications; OEM authorised by GE, Honeywell, Solar Turbine) with Flysquawk's local industry knowledge — delivering certified MRO solutions that extend equipment life, reduce downtime, and support Malaysia's industrial sustainability goals.

To be ASEAN's leading restoration-based MRO partner — preserving legacy industrial assets, protecting capital, and enabling a financially and environmentally sustainable future.

Opened NewCo (new company) named Flysquawk Integrated to replace domain Flysquawk Sdn Bhd. Managed Boeing 747 (9M-MPD) acquisition and disposal project under Malaysia Insolvency Department, showcasing complex cross-agency coordination.

Initiated collaboration with PT Nusantara Turbin dan Propulsi (NTP) for Overseas Training Aircrafts Engine Rectification.

Appointed as MRO Partner for Rotating Equipment in Malaysia's Palm Oil Industry, covering steam turbines, centrifugal compressors, centrifugal pumps, and reverse engineering services.

"Old is Gold — if cared for by the right hands."

While others rush to replace, we restore. We believe the machines that powered Malaysia's industrial growth — built by skilled engineers and craftsmen of earlier generations — deserve a second life, not a scrapyard.

Every turbine overhauled, every compressor reconditioned, every pump restored carries forward the legacy of those who designed and built them. We honour their craftsmanship by preserving what they created — extending equipment life through technical precision, patience, and respect for engineering heritage.

This is not just repair work. It is industrial stewardship — protecting customer capital, reducing environmental waste, and uplifting the communities who depend on reliable, sustainable industrial infrastructure.

We respect and learn from elderly engineers who built Malaysia's industrial foundation — preserving their knowledge, celebrating their craftsmanship, and passing their wisdom to the next generation of technicians and engineers.

Restoration is the most natural form of sustainability. By extending equipment life through precision MRO, we reduce industrial waste, lower carbon emissions from manufacturing replacements, and support decarbonisation through energy-efficient refurbishment.

We invest in local talent development, skilled trades training, and community partnerships — creating jobs, transferring technical skills, and strengthening the industrial workforce that powers Malaysia's plantation and energy sectors.

We celebrate the artistry of hands-on craftsmanship — the precision of manual machining, the patience of reverse engineering, and the pride of restoring a 30-year-old turbine to peak performance through skill and dedication.

Office: Cyberjaya, Selangor

Scope: Client liaison, inspection coordination, project management

"Old is Gold — if cared for by the right hands."

While others rush to replace, we restore. We bring old turbines and compressors back to life with precision, patience, and passion — preserving the machines that once powered Malaysia's growth.

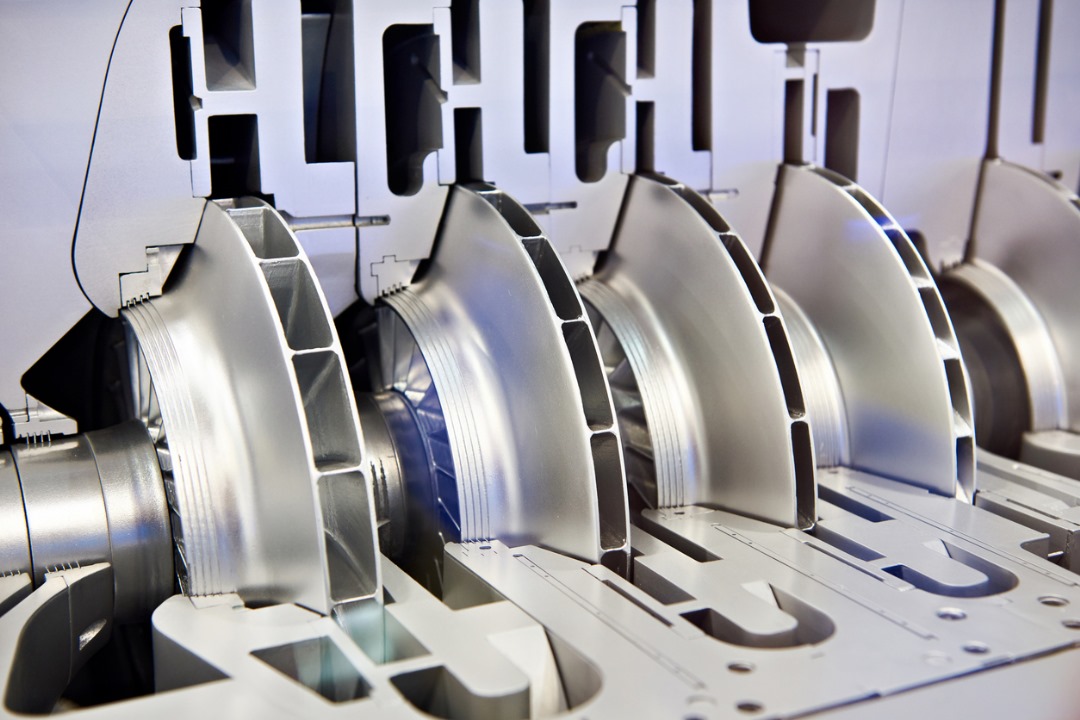

Precision restoration for steam turbines up to 4MW.

With the collaboration with our principal in Indonesia, we believe their engineer experience and expertise, we can perform reverse engineering and manufacturing of steam turbines up to 4MW. One of the turbines that we produced is still operating and running well at Kamojang Geothermal Power Plant.

Our service team is always ready to provide specific and precise industrial services to meet your company needs with certified workmanship & guaranteed reliability.

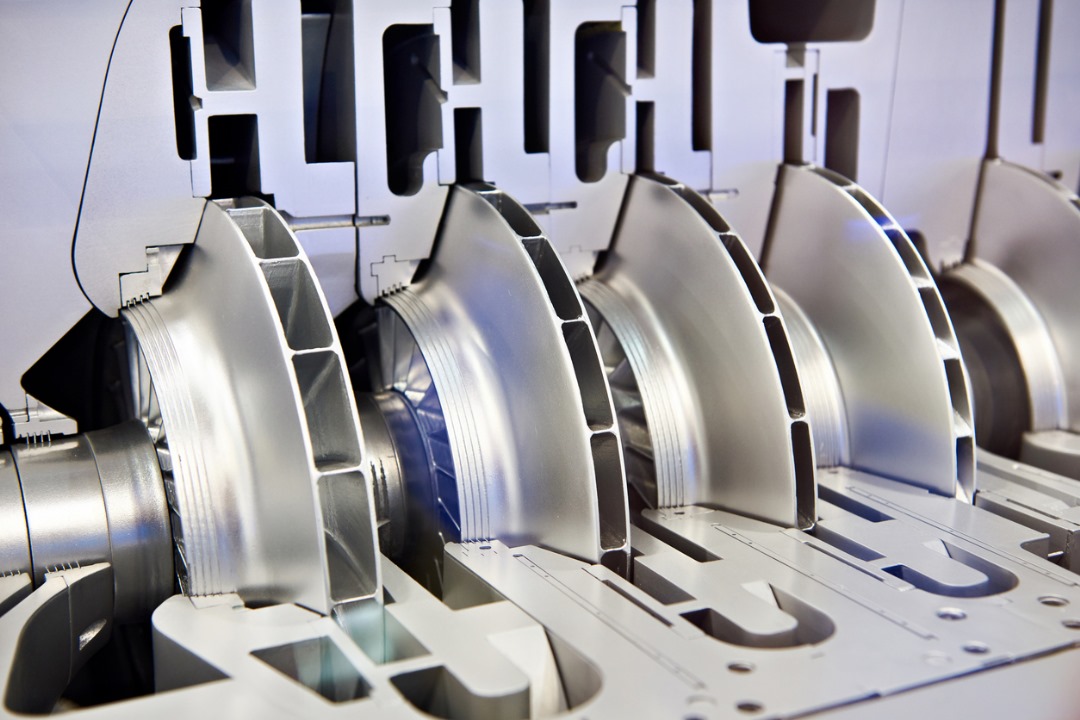

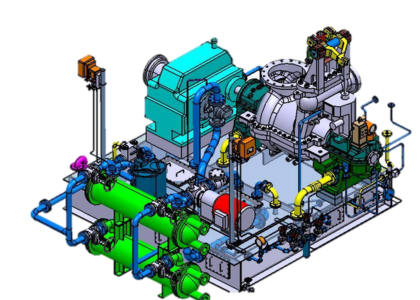

Advanced compressor restoration and manufacturing services.

Our centrifugal compressor services combine decades of engineering expertise with state-of-the-art facilities to deliver comprehensive restoration and manufacturing solutions.

From precision machining to complete overhauls, we ensure your compressors operate at peak efficiency with extended service life and enhanced reliability.

Restoring pump performance with long-term reliability.

Our centrifugal pump restoration services combine precision engineering with decades of experience to deliver reliable, long-lasting solutions for critical industrial applications.

Joint expertise with PT Nusantara Turbin dan Propulsi (NTP).

Flysquawk Integrated, in partnership with PT Nusantara Turbin dan Propulsi (NTP), delivers comprehensive field services combining 36+ years of certified aviation and industrial expertise with local Malaysian market knowledge.

Ensuring the integrity of your critical equipment.

Non-Destructive Testing (NDT) plays a critical role in ensuring the safety, reliability, and performance of rotating equipment such as turbines, compressors, and pumps.

Together with our principal PT Nusantara Turbin dan Propulsi (NTP), Flysquawk provides certified NDT services to detect cracks, defects, corrosion, weld failures, and internal damage — without dismantling or harming the equipment.

NDT helps plants reduce downtime, prevent catastrophic failures, extend equipment lifespan, and protect both personnel and assets.

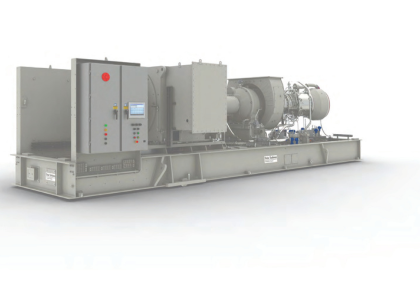

Authorized service capabilities for Solar Turbine gas turbines.

Backed by the strength of our principal PT Nusantara Turbin dan Propulsi (NTP), Flysquawk Integrated provides complete lifecycle support for Solar Turbine (Caterpillar Group) gas turbines — from inspection and refurbishment to full Level 4 overhaul.

NTP has been the Authorized Maintenance Center (AMC) for Solar Turbine since 1987 and is recognised as a leading overhaul facility in the Asia Pacific region. This long-standing capability allows us to deliver OEM-standard quality, ensuring your turbines run reliably and efficiently — even in demanding industrial environments.

Whether offshore, onshore, or industrial power applications, Solar Turbine units remain among the most trusted in the world. Through our collaboration, Flysquawk ensures these engines continue to perform at their best.

Aero-derivative turbine overhaul, repair, and field services.

Flysquawk Integrated, through our strategic partnership with PT Nusantara Turbin dan Propulsi (NTP), provides comprehensive maintenance and overhaul services for General Electric (GE) gas turbines.

Our certified capabilities cover aero-derivative turbine technology, ensuring reliable operation and extended service life for critical power generation applications.

"Every project tells a story of restoration, precision, and partnership."

Flysquawk Integrated Sdn Bhd, together with PT Nusantara Turbin dan Propulsi (NTP), continues to deliver cross-industry engineering solutions that merge aviation discipline with industrial reliability.

Flysquawk Integrated — Reviving legacy assets. Restoring performance. Protecting capital.

Level 15, DPulze, Lingkaran Cyberpoint Timur, Cyber 12, 63000 Cyberjaya, Malaysia

+60 19 986 9487

enquiry@flysquawk.com.my

45,000 m² Advanced MRO Facility

Bandung, Indonesia